Steven Vanlerberghe

A volume seeder seeds a certain ‘volume’ of seeds and distributes them equally on the pot or tray cell surface.

Therefore, the equipment is provided with removable distribution tubes.

The perforated seed plates are available in various thicknesses and with different perforations so a very wide range of seeds can be processed.

The volume seeder can be assembled on a standard potting machine or on a conveyor belt.

Full-automatic operation.

The pneumatic needle seeder vacuums 1 seed per needle (vacuum) and blows off into the pot or tray cell.

The seeding bars are made to size of the trays.

The seed is vacuumed from an open vibrating seed reservoir.

A packet of standard needles is supplied, a very wide range of seeds can be processed with them.

The seeder always provides a seeding hole by means of a dibbler bar.

The vacuum strength, blowing off strength and vibration are infinitely adjustable so the machine can accurately be set for every single task.

This seeder is assembled on a soil blocker.

Needle seeders are best used to seed small quantities. They can easily be converted.

Big bale opener based on tilting mechanism, hydraulically driven.

At outfeed side provided with a breaker and a spraying tube for humidification.

Automatic operation by means of photocell.

Fit with wheels and drawbar for moving.

De demtec draairobot is inzetbaar voor alle potmaten in combinatie met alle kweektafels.

Hij is gemaakt van duurzame materialen, is zeer eenvoudig programmeerbaar en werkt zeer nauwkeurig.

Dit laat een aanzienlijke arbeidsbesparing toe.

Bovendien is dit degelijke concept veel economischer dan andere systemen en kent het een verrassend hoge capaciteit.

Hij kan geïntegreerd worden in eender welke omgeving en werkt feilloos in combinatie met andere transportsystemen.

Often, a roller conveyor is a cheap alternative for another conveying system.

After all, a roller conveyor that is installed on an inclined surface moves a tray without using any energy.

Our range includes roller conveyors of all widths and various lengths.

They can be purchased pre-assembled or you can choose to buy the cheaper building kit.

Our roller conveyors are abrasion-resistant and extremely practical for horticultural use.

Besides non-driven roller conveyors we also manufacture driven roller conveyors in light (trays or crates) and heavy (fully loaded pallets) versions.

Since a few years an increasing number of plants is cultivated in trays.

Trays are easier to manipulate.

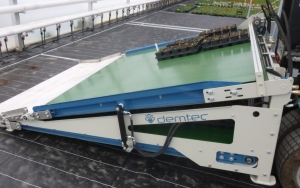

Demtec has developed some placing conveyors for trays.

They are installed on an existing transport equipment (forklift truck, tele-handler, tractor, etc.) and easily place a packet of trays.

The belt can be controlled electrically or hydraulically, and depending on the used trays the placing belt can withdraw the trays.

For even larger volumes a self-driving placing belt can be supplied.

More often plants are pre-sorted during cultivation.

During this sorting it might be necessary to treat them: trim, weed, remove dead leaves, etc.

Before shipment they are checked again and material that is not ready for shipment, is placed back.

In short, plants are frequently picked up, which is a hard job.

If you pick up your plants with a fork, you could put them on a degrouping conveyor.

The pots are neatly put in a single line and the work is done at a belt.

When sorting at a belt, you can do the work much faster, the sorting is done better and ergonomically, it is better to work this way.

Also other work is smoother and can, if required, be done by machines: labelling, blowing out, washing of pots, trimming, etc.

Demtec implements full processing lines to size of your company and in accordance with the plants.

A durable transport fork is essential for a smooth discharge and picking up of pots and/or trays.

We manufacture forks with the required width.

Our fork range includes both single and double layered forks and they are always manufactured in function of their load (no deflection of arms).

They are easy to connect and remove (you do not have to step down from the forklift truck) and they are made out of the best quality material.

We developed a series of grouping conveyors for various applications.

Besides standard sizes, customized manufacturing is possible.

Equipped with a very customer-friendly universal software that can place all types of pots in any configuration.

We supply single and double pot forks made to size and advise you on the best fit forklift truck.

After all, every subsoil and every cultivation needs to be approached differently.

Many companies use conveyor belts for internal transport of pots, trays and/or crates.

They are used to fill the greenhouse, to replace cultivations and, more often, to empty cultivation beds.

Demtec offers high-quality horticultural conveyor belts that comply with your specific demands.

Available in widths from 17cm upto 60cm and of all possible lengths.

Besides mobile conveyor belts, our range also includes stationary greenhouse belts.

Conveyor packets can consist out of one central motor conveyor that drives the slave conveyors by means of universal joints.

Besides, belts with separate engines are available as well.